Application of Infrared Thermal Imaging in Intelligent Manufacturing

In the application fields of food packaging, automobile manufacturing, semiconductor and electronic manufacturing, infrared thermal imaging can be used to continuously monitor and detect the irregular distribution of heat, so as to improve productivity. As a long-distance non-contact temperature measuring technology, infrared thermal imaging can be widely used in intelligent manufacturing process. It plays the key role in detection and control in the production process.

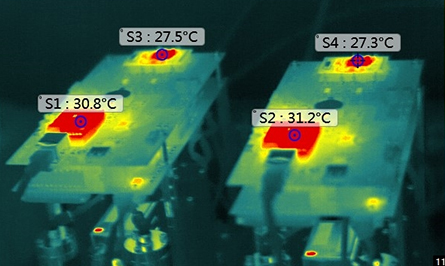

Electronic manufacturing

When circuit components are working, the generated heat will be different due to different currents passing through the components and different power consumption of the components, which will be reflected on the surface of the components in the form of temperature difference.

Recommended product

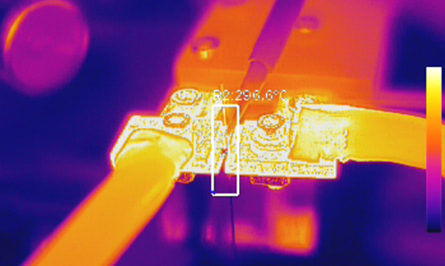

Optical fiber splicing temperature monitoring

The temperature of the splicing joint shall be measured in real-time during the whole splicing process. After the temperature reaches the set value, such as the melting point temperature of the flux, the signal shall be given to the splicing equipment to stop heating up, and the operator may confirm the flux melting and splicing combined with the optical imaging system.

Recommended product

Truck suspension vibration test

The test on the overall vibration fatigue durability of trucks is particularly focused on the durability of leaf spring elastic elements. In the process of vibration, the temperature of the leaf spring would rise obviously. The whole testing process can be monitored with a thermographic camera to obtain the rising trend of temperature of the whole process.

Recommended product

Detection of hot melt adhesive on packing crates

In the field of food packaging, infrared thermal imaging can be used to continuously monitor and detect the irregular distribution of heat and then determine whether there is adhesive on the packing boxes or not, so as to improve productivity.

Recommended product